Self-Feeder Management

Posted: September 19, 2019 | Written By: Don Cleaver, Form-A-Feed Livestock and Nutrition Specialist

Self-feeders have long been used in the beef industry as an effective means to feed cattle in a variety of cattle feeding operation types, from a backyard 4-H herd, to a large-scale feedlot. Self-feeders work effectively in cow-calf operations to creep feed beef calves as well as for confinement feedlot cattle. Self-feeders require less labor than other feeding methods, make efficient use of feed by controlling waste and spillage, and can reduce equipment and fuel usage.

Self-feeders can be made from wood, metal, or plastic. There are four main types of self-feeders: portable, stationary, homemade, and flex systems. The portable type of feeder is often referred to as a creep feeder. They tend to be used for smaller calves on pasture and have a gate system to prevent larger animals from accessing the feed.

TYPES OF SELF-FEEDERS:

Calf creep feeder – portable

Creep feeding tips:

- Locate the feeder close to water, shade, mineral tubs, or any area that cows frequent.

- Allow 4-6 inches of trough space per calf.

- Sprinkle some feed on the ground near the feeder to entice calves.

- Clean and adjust feeders often.

- Do not let the feeders run out.

Stationary self-feeders

Homemade Feeder

Flex System

Delivers feed into a bunk on a keep-fill basis with flex-augers and automatic shut-off switches.

RESEARCH ON SELF-FEEDERS:

According to testimonials of one manufacturer, the labor for feeding was 4.5 times less with a stuffer than a bunk. They also reported a 5% decrease in feed waste over bunks.

Another report* from NDSU compared finishing diets fed by bunk and self-feeders. The results showed only a 10 cent per head advantage to the bunk fed cattle vs. self-fed cattle. The economic breakdown did not place any value on labor. When factoring in labor the self-feeder is the best option for small to mid-sized operations.

These results are only achievable when the feeder is managed properly.

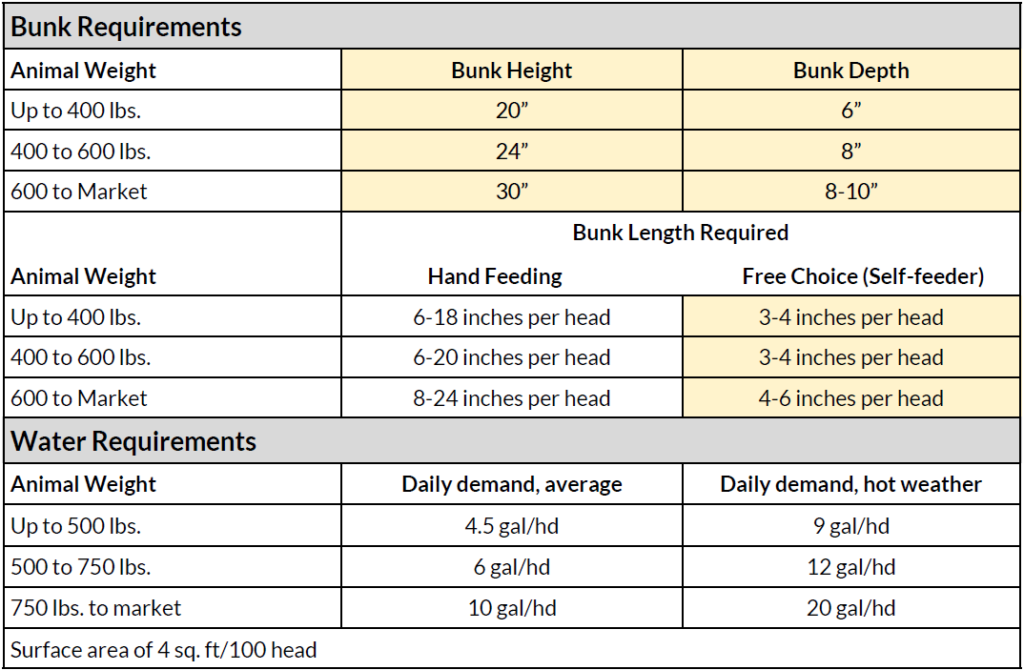

SIZING/BUNK REQUIREMENTS:

Sizing:

8’ feeder using both sides= 192 inches

• 64 hd under 600#

• 48 hd over 600#

10’ feeder using both sides= 240 inches

• 80 hd under 600#

• 60 hd over 600#

Consider multiple smaller feeders rather than one large one. This can help spread out the animals and offer a feed source if one of them gets plugged.

When a feeder gets plugged from the inside, the useable bunk space is reduced and performance will suffer.

-

Control waste and spillage -

Well-managed feeder

You never want an empty feeder, however you do not want them too full either. The bottom of the feed pan should be visible as in this photo.

Rodent control

Eliminating or controlling rodents will also reduce the spread of diseases. Rats and mice can carry infected fecal matter and other materials from pen to pen on their coats. Close any possible entrances to feed storage areas and to any closed barns or facilities. Commercial rat and mice poisons are effective in reducing rodent populations. Take precautions when placing the bait so they are not accessible to cattle or pets.

MAINTENANCE:

Daily

• Check the feeder to be sure feed is available and flowing. This is especially important in adverse weather conditions. In winter, ice and snow can build up and block flow.

• Look to see if there is anything that may be obstructing the path to the feeder (mud, fallen gates or other objects they need to walk around). If mud is often present, build up the area to drain well.

• When a Holstein can’t easily get up to the feed and water, they just lay down and wait. This means poor performance and an increase in the chances of digestive issues.

Weekly

• Clean out fines.

• Toss any feed that is moldy. You can put the non-moldy fines in a bunk or empty tub away from the feeder to give the cattle another chance to eat them.

• When a feeder is cleaned there is a good chance mold will be disturbed. If a person is sensitive to mold, it is a good idea to wear a protective mask.

• One way to reduce the need to clean stuffers more often is to screen the corn. This is especially helpful for younger calves that will back down on intakes with a lot of fines.

• Be sure to inspect the water sources as well. Drain and clean often.

Spring and Fall

• Adjust the openings accordingly. Over time cattle can and will work the adjustable slides up. It is important to limit the opening to ¾” in the summer and 1” in the winter.

• There are 2 main reasons to keep the openings low.

• One is to make the cattle work to get the feed out. This helps them create saliva to buffer the rumen and in turn reduce the chances of slug feeding.

• The second is to keep the pellets inside the feeder right up until the cattle eat them. This helps reduce the pellet fines in the feeder tray.

• Other ways to reduce pellet fines are to put them in the mixer last, mix for 20 seconds and start emptying the mixer, be sure your pellet bin is emptied and cleaned out at least two times per year.

• Spot check the scales on your mixing equipment too.

Annually

• Clean out all remaining feed and lift the feeder up to power wash the mud and manure off.

• Check the site for signs of rodents.

• Patch any holes and seal any cracks with silicone. This is a good time to apply another coat of paint.

• Check hardware such as hinges, adjusting bolts, and latches and replace if needed.

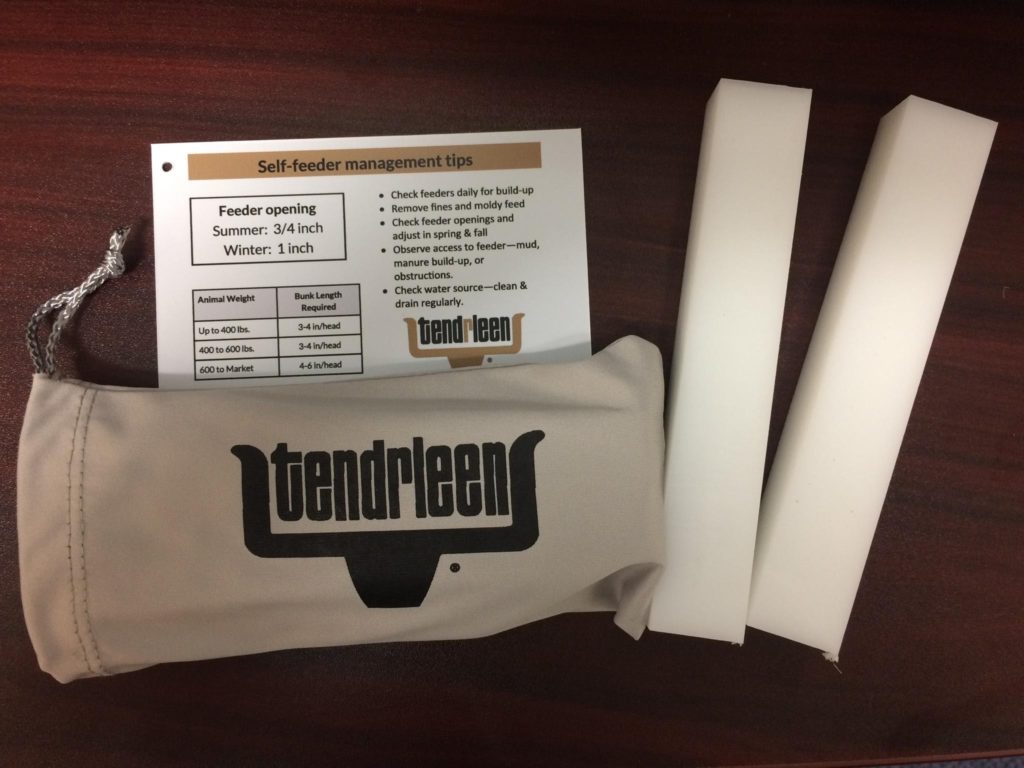

Tools Needed:

• Adjustable wrench

• Pry bar

• Screwdriver

• Form-A-Feed adjusting

blocks

• Hammer

• Tape measure

• Trowel

• Empty tub

Form-A-Feed Tend-R-Leen Adjusting Blocks

Would you like a set of free Form-A-Feed Tend-R-Leen adjusting blocks for your self-feeder? Just fill out the form below to receive your free blocks (while supplies last)! Be sure to contact your Form-A-Feed representative for help with feeding management strategies for your self-fed cattle!

Self-Feeder Adjusting Blocks Request Form

*Research citings available upon request.